Making confident decisions early on can determine whether a project stays within budget and schedule or risks overruns. Yet, early estimates are often made with limited data, leaving room for uncertainty. This is where cost modeling software makes a difference.

Cost modeling software allows project professionals to build cost models that capture historical knowledge, engineering data, and cost estimate relationships (CERs). These models help organizations generate consistent, reliable, and data-driven estimates, even in the earliest phases of a project.

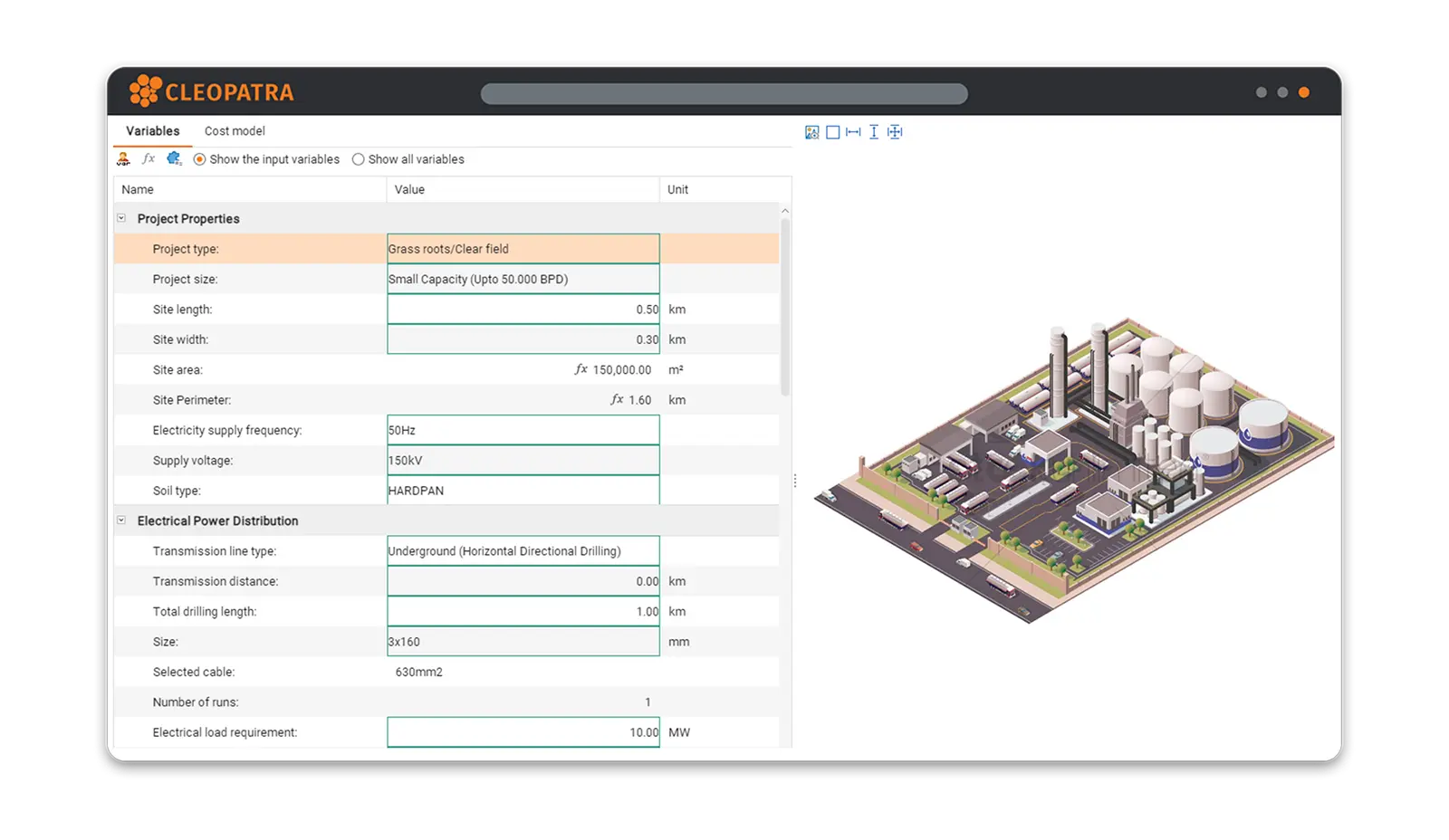

Cleopatra Enterprise empowers you to use your own cost models and techniques in a state-of-the-art cost estimating software. With its advanced capabilities, you can both implement proven models and design new ones tailored to your organization. This ensures your team benefits from a structured, repeatable, and scalable way of working with costs.

Below are four examples of cost models you can create with Cleopatra Enterprise.

4 Powerful Cost Models You Can Build with Cleopatra Enterprise

There is no one-size-fits-all method for cost estimating. Different approaches are required depending on the level of detail, data availability, and project stage. Cost modeling software like Cleopatra Enterprise allows you to build and apply a variety of models that match these conditions. Here are four practical examples:

Capacity scaling model

A quick but very powerful technique of estimating projects up front is capacity scaling. By analyzing previous projects in detail using the Project Analytics module of Cleopatra Enterprise, you are able to study and extract scaling factors to setup cost estimation models. For example, below you see a take-off sheet for estimating the cost of a new plant. After choosing the type of plant (in this case, for making Polypropylene), the model automatically determines the proper capacity scaling factor. After the user enters the cost of the reference plant and capacity, the model calculates the new project cost:

Parametric cost model

Another type of cost estimation model is a parametric cost model, based on one or more cost estimate relationships (CERs). Cleopatra Enterprise has an advanced regression analysis subsystem that reports correlations between technical parameters of equipment and its cost, installation hours, weight, etc.

The take-off sheet contains variables that you fill in manually and others might be calculated automatically. It’s even possible to create a model with variables that get a default value based on a calculation that you can later overwrite or return to its auto-calculated value. The status bar shows the boundary conditions of the parameter currently selected, in this case the pump duty.

Physical cost model

When you know more about a specific design that you frequently use, you can set up a physical cost model that simulates building the equipment within the model. For example, the costs of a storage tank might be calculated by virtually determining the amount of plates and welding each plate, generating the expected amount of cost, hours and weight for the tank. An example model is shown below:

The model calculated physical properties like wall thickness, secondary steel, electrical components, and more. From this, the amount of steel is calculated. A price curve in the background then calculates the cost and amount of installation hours.

Dynamic assemblies

The cost estimation models above can also be expanded to include quantities for the related disciplines like piping, insulation and painting. From the wall thickness, pressure and material type, the type of pipe can be determined from engineering standards that are included in the model. Temperature and surface area can determine the amount of insulation material and painting. The result is that the cost estimator can obtain quantities early on in the project, when only the equipment list is known. The user has a lot of freedom creating this type of cost estimation model, so that you are able to incorporate your own design standards in cost models. Below you see a storage tank estimate component, sub-structured with pipelines, installation cost and insulation:

Why Use Cost Modeling Software

Beyond generating estimates, cost modeling software provides several strategic benefits:

- Consistency across projects: Using standardized models prevents discrepancies and ensures repeatable outcomes.

- Time savings: Automating calculations reduces manual effort and frees time for analysis.

- Greater accuracy: Cost models use real project data and relationships, which improves reliability.

- Better risk management: Sensitivity analysis highlights key cost drivers and uncertainties early.

- Knowledge retention: Cost models embed organizational expertise, ensuring lessons learned are preserved and can be easily reused.

By integrating these benefits into your workflow, your team can move from reactive estimating to proactive decision-making.

Build Your Own Advanced Cost Models

The four examples above show only a glimpse of what Cleopatra Enterprise makes possible. With its flexible architecture, you can develop cost models that reflect your company’s data, standards, and ways of working.

Whether your focus is scaling factors, parametric relationships, physical details, or dynamic assemblies, Cleopatra allows you to create advanced, customized models. This ensures your cost estimating process grows in maturity and delivers more value over time.

Try Cleopatra’s Cost Modeling Software

Are you ready to strengthen your estimating process with state-of-the-art cost modeling software? Cleopatra Enterprise helps you design, apply, and evolve cost models that bring clarity and confidence to your projects.

Request a demo or explore our cost estimating software page to learn more.

Managing a project and keeping it under “control” can be an extremely challenging process. That’s where project controls…

Project costs are derived from the required resources needed to complete the objective, which might be anything from…

Related resources

Parametric estimating in project management

Parametric estimating for estimating projects is a technique that involves using mathematical relationships and statistical analysis to develop cost estimates based on a set of parameters or variables. Instead of relying solely on engineering input or detailed project specifications, it leverages the relationship between various project characteristics to derive cost…

Parametric estimating for estimating projects is a technique that involves using mathematical relationships and statistical analysis to develop…

Read blog articleResource-Based vs Activity-Based Estimating Software

The pros and cons of Resource based estimating and activity based estimating.

The pros and cons of Resource based estimating and activity based estimating.

Read blog article