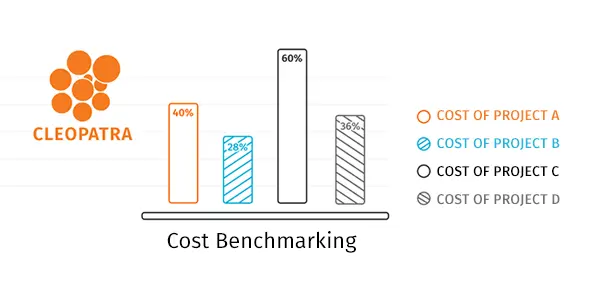

In today’s ever-changing markets, large capital projects face increasing pressure to deliver on time and within budget. Project teams need tools and strategies that enable them to compare their performance against proven standards and identify opportunities for improvement. Cost benchmarking is key to achieving this. By systematically comparing project data against industry benchmarks, companies can evaluate performance, reduce risks, and enhance predictability.

Understanding Cost Benchmarking

In project management, controlling costs is critical to success. Cost benchmarking provides a structured way to evaluate project costs, compare them to relevant standards, and identify opportunities for improvement.

Definition of Cost Benchmarking

Cost benchmarking is the practice of comparing project costs against historical data or established standards across similar projects. It involves collecting, analyzing, and comparing cost data to uncover performance gaps and opportunities for efficiency.

Benchmarks may include metrics such as cost per unit installed, cost per square meter, or cost per capacity unit (e.g., $/MW for energy projects). When applied consistently, benchmarking ensures cost estimates remain realistic and aligned with market conditions.

Cost benchmarking also enables organizations to evaluate whether estimates, budgets, and expenditures are competitive. It strengthens predictability by improving cost data for estimating processes, creating checks and metrics to ensure budgets stay aligned with expectations, and helping teams assess performance and budgets with internal and external entities.

Internal vs. External Benchmarking

Cost benchmarking can be applied in two distinct ways: internal benchmarking and external benchmarking.

- Internal benchmarking compares project performance across different business units, locations, or time periods within the same organization. It helps organizations identify recurring inefficiencies and spread best practices internally. For instance, comparing costs across regional offices or between completed and ongoing projects can highlight opportunities for optimization.

- External benchmarking, on the other hand, compares an organization’s project costs against industry peers or market-wide data. This type of benchmarking provides a reality check, ensuring that internal practices are competitive with global standards. External benchmarking is particularly valuable for organizations executing large capital projects in highly competitive sectors, as it reveals whether cost structures are aligned with industry leaders.

Combining both approaches gives organizations a well-rounded view: internal benchmarking drives continuous improvement within the company, while external benchmarking validates competitiveness in the broader market.

Benefits of Benchmarking Project Costs

The advantages of cost benchmarking in project management are clear:

- Improved Cost Accuracy: Ensures estimates and budgets are aligned with industry reality.

- Enhanced Decision-Making: Provides data-driven insights for project managers, sponsors, and stakeholders.

- Risk Reduction: Identifies areas where costs deviate significantly from norms, highlighting potential risks early.

- Performance Optimization: Reveals efficiency opportunities and best practices from successful projects.

- Stakeholder Confidence: Increases trust in the financial planning and investment process through evidence-based metrics.

Implementing Cost Benchmarking in Projects

To implement cost benchmarking effectively, organizations should follow a structured approach:

- Collect data: Gather accurate cost and performance data from previous projects or industry databases. Tools like Cleopatra Enterprise provide a structured way to consolidate such data.

- Normalize data: Adjust costs for factors such as currency, location, inflation, and scope to ensure comparability.

- Develop benchmarks: Define key performance indicators (KPIs) and benchmarks relevant to the type of project (e.g., construction, energy, infrastructure).

- Analyze and compare: Compare current project costs with benchmarks to identify variances and understand the reasons behind them.

- Implement improvements continuously: Apply findings to refine future estimates, enhance predictability, and close performance gaps.

The benchmarking process is not a one-time exercise. It should be integrated into the overall cost management framework to maximize its value. Furthermore, while benchmarking can be done manually, integrated solutions like Cleopatra’s capital project management software enhance efficiency and consistency, allowing project teams to focus on applying insights rather than gathering data.

Examples of Cost Benchmarking in Projects

Cost benchmarking has been successfully applied across industries to improve project performance. For example:

- Construction Projects: In the construction industry, benchmarking has been used to measure productivity rates, cost per unit, and schedule performance. For example, companies benchmark construction costs across multiple regions to determine the most competitive pricing models.

- Energy and Infrastructure Projects: Benchmarking helps identify cost outliers in large-scale energy facilities, such as power plants, ensuring that costs per installed megawatt remain competitive with global standards.

A Real-World Application: Enbridge’s Estimating and Benchmarking Success

Enbridge, a major player in the energy sector, faced challenges in aligning cost models with the most recent project costs, evaluating performance across projects, and adapting to shifting market conditions. The company sought a flexible solution to enable enterprise-wide benchmarking and more accurate cost estimation.

By implementing Cleopatra Enterprise’s project controls software, Enbridge was able to consolidate and maintain cost models more efficiently, capture detailed cost data from executed and ongoing projects, and establish robust benchmarks for performance comparison. The platform’s flexible reporting tools allowed teams to adapt cost analyses to specific project needs.

These improvements allowed Enbridge to detect deviations early, enhance estimate accuracy, and strengthen stakeholder confidence. Integrating cost benchmarking into their cost management process significantly improved decision-making and project execution efficiency. Read the full Enbridge case study.

Conclusion

Cost benchmarking is a strategic practice that empowers organizations to manage large capital projects more effectively and achieve more predictable outcomes. By defining benchmarks, comparing performance against industry standards, and applying insights to future planning, project teams can reduce risks, improve predictability, and drive better outcomes.

In an industry where even small cost deviations can have major financial implications, cost benchmarking provides the clarity and control necessary for success. Whether in energy, construction, or infrastructure, cost benchmarking ensures that projects remain competitive and stakeholders stay confident in the project’s financial health.

According to Dodge Construction Network’s survey, 70% of owners and contractors agree that better communication and coordination across…

Operational efficiency in project management is about achieving more with less: delivering projects on time and within budget…

Related resources

Enbridge’s Cost Estimation and Benchmarking Success

See how Enbridge used Cleopatra to enhance cost estimating and benchmarking, resulting in saving time and supporting key decisions.

See how Enbridge used Cleopatra to enhance cost estimating and benchmarking, resulting in saving time and supporting key decisions.

Read case study

Construction Industry Project Benchmarking: 3 Best Practices

Project benchmarking is used to improve the cost performance of companies. There are different methods of benchmarking: internal, competitors and strategic.

Read blog article