What is parametric estimating?

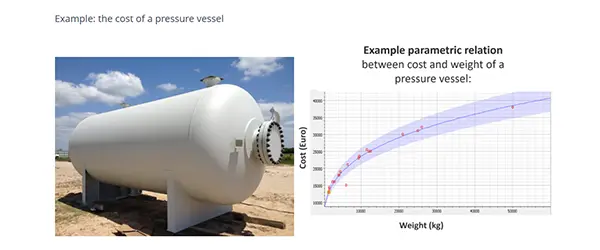

Parametric estimating for estimating projects is a technique that involves using mathematical relationships and statistical analysis to develop cost estimates based on a set of parameters or variables. Instead of relying solely on engineering input or detailed project specifications, it leverages the relationship between various project characteristics to derive cost estimates in this very early stage in which an estimate could be required.

In simpler terms, parametric estimating looks at the key drivers or factors that influence historical project costs and establishes mathematical equations or models to express these relationships. These models can then be used to predict costs for new projects based on their specific attributes.

Get a good basis so that you can later use it for cost control and project controls. Good project cost management starts with good cost estimating software, which should give a user the option of parametric modeling and use historical information for this.

Parametric modeling (probabilistic vs deterministic)

In parametric modeling, the way results are presented can vary based on the amount of uncertainty you wish to account for. The two main types of estimates are deterministic and probabilistic.

Deterministic Estimates

A deterministic estimate provides a single value based on a set of known parameters. For example, if the cost per unit of work is $100, and the project requires 10,000 units, the estimate would be $1 million. It is calculated based on fixed inputs using a model or formula. This type of estimate is straightforward and useful when you have clear data and the project is relatively well-defined. You might still fine-tune the result based by applying expert judgment, adjusting for project-specific conditions, or including a contingency. However, the outcome will remain a single number.

Probabilistic Estimates

In contrast, a probabilistic estimate doesn’t land on just one number, it provides a range of possible outcomes. Unlike deterministic estimates, probabilistic estimates account for uncertainty and help project managers understand the variability in costs or duration. This is especially the case in the early stages of the project. This approach typically identifies three key points: the optimistic scenario (best case), the most likely scenario (the estimate with the highest probability), and the pessimistic scenario (worst case). By plotting these values on a probability curve, a clearer picture of potential risks becomes possible and helps you plan for the full range of possible project outcomes.

What are the key benefits of parametric modeling?

- Parametric models allow for quick cost estimation, especially in the early stages of a project when detailed information may be limited.

- Consistent methodology for estimating costs across various projects.

- Allows for flexibility in incorporating project-specific variables, ensuring that the estimates remain relevant and accurate.

- Generates a data-driven estimate, leading to more informed decision-making.

- Allows for scenario analysis, enabling project managers to explore the impact of changes in project parameters on overall costs.

In summary, parametric modeling enhances the speed, consistency, and accuracy of cost estimation, making it a valuable tool in project management for effective decision-making and resource planning.

Limitations of parametric estimating

While parametric estimating can speed up early-phase cost predictions by leveraging mathematical models and historical data, its accuracy and usefulness depend on several important factors:

- Parametric models are only as accurate as the data behind them. Outdated, inconsistent, or poorly documented data can result in misleading estimates.

- Models have predefined boundaries and assumptions, leading to limited accuracy. If your project falls outside those assumptions, the estimate may miss the mark.

- In some industries or for highly unique projects, relevant and scalable parametric models may not be readily available or applicable.

- Collecting and organizing the necessary historical data can be time-consuming, especially if data is spread across different sources or lacks standardization.

- Even well-established models need to be calibrated for specific project conditions, such as team experience, geographic location, or current market rates.

- Parametric models help you to get started, but you should update the estimate as more (engineering) information becomes available and therefore apply different cost estimation methodologies.

Note that data for this methodology improves over time as more information becomes available. The more flexibility your cost estimation software has for benchmarking, the better your results will be. Some parties even provide software with out-of-the-box cost models, which can be both a huge time and budget saver.

When to use the parametric estimating technique?

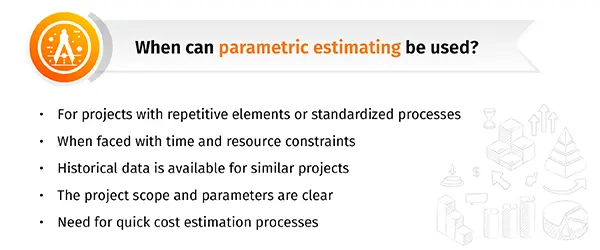

Parametric estimating is a valuable technique suited for specific project scenarios where streamlined, rapid estimation processes are essential. It leverages historical data and standardized approaches to deliver efficient cost projections. Here are the key conditions under which parametric estimating is most effective:

- Projects with repetitive elements or standardized processes benefit from parametric modeling due to the ability to apply predetermined cost factors based on historical data.

- When faced with time and resource constraints, such as tight deadlines or limited access to project data, parametric modeling offers a practical solution. By relying on predefined cost models and parameters, estimators can quickly generate reliable cost projections without extensive data collection.

- When historical data is available for similar projects. With this information cost estimators can establish cost relationships and predict future project costs more confidently.

- A clear understanding of the project scope and parameters is essential for successful parametric estimating. Well-defined scopes and parameters enable accurate application of cost factors and assumptions, leading to more precise cost projections.

- Parametric estimating becomes an attractive option when there is a need for quick and efficient estimation processes. Its standardized approaches and predefined cost models speed up decision-making and project planning.

However, it’s important to note that if project complexity varies significantly or detailed data is lacking, traditional estimation methods may be more appropriate.

Where does parametric estimating fit in the cost estimation lifecycle?

The parametric estimating technique is typically used in the early stages of a project, such as during scenario analysis or feasibility studies, when high-level estimates (class 5 estimates according to AACE’s Cost Estimate Classification System) are needed quickly. At this point, the project’s scope is still being defined, and detailed information is limited. Parametric estimating is particularly effective here because it relies on historical data and mathematical models to create broad estimates based on key project parameters, such as cost per unit, labor cost, or even size of the project.

As a project progresses and more information becomes available, the cost estimation methods evolve, moving from broad, high-level approximations to more detailed, refined estimates. During later stages, methods like unit rate estimating and detailed estimating become more appropriate as the project scope is clarified and data becomes more specific.

Tips & tricks for parametric estimating in novel technologies

New technology or new ‘’sized’’ equipment comes with the unique challenge of creating parametric models for them. The challenge here is to link unknown components to the balance of the plant, which is mostly still known by the estimator. New technology often comes with new equipment, but still has a large chunk of project scope, which isn’t new.

Therefore, to create parametric estimates for novel technologies you can start by:

- Gathering information from licensor proposals, historical project information and publications.

- Finding relevant cost drivers for core technology (flow rate, heat exchange area, weight, etc.).

- Linking the cost of core technology to balance of the plant or project.

- Linking the factors of the cost drivers to disciplines and labour/materials.

How Cleopatra can help with parametric estimating

When it comes to parametric estimating, Cleopatra Enterprise’s cost estimating software can enhance the accuracy and efficiency of cost estimates by leveraging advanced cost models and historical data. By integrating reliable cost and labor norm knowledgebase like CESK (over 1.5 million cost items from 2,000+ real-life projects), project teams can build parametric estimates based on proven statistical relationships, ensuring precision even in the early stages of a project.

Whether you are improving your cost management processes or simply don’t have enough resources to support your projects,…

This guide will walk you through the critical aspects of cost estimation, including key principles, the importance of…

FAQs

-

Analogous vs parametric estimating: what’s the difference?

Analogous and parametric estimating are both top-down techniques used to estimate costs, durations, or resources in a project. While they both rely on historical data, the way they use it differs:

- Analogous estimating uses historical data from similar projects but relies heavily on expert judgment to make quick, rough estimates. This method is faster but less precise because it involves comparisons to past projects without detailed modeling.

- Parametric estimating also uses historical data, but it applies mathematical models and statistical relationships to make more accurate estimates. By using specific parameters (like cost per unit or time per task), it calculates projections based on real data and established models, leading to more precise forecasts.

In short, analogous estimating is based on expert judgment using past projects, while parametric estimating uses statistical models and data to generate more precise estimates.

Related resources

5 cost estimation techniques supported by Cleopatra's software

Learn which project cost estimating techniques you can apply with an advanced software tool to develop more accurate cost estimates for your projects.

Learn which project cost estimating techniques you can apply with an advanced software tool to develop more accurate…

Read blog articleWhat is Cost Modeling Software?

Making confident decisions early on can determine whether a project stays within budget and schedule or risks overruns. Yet, early estimates are often made with limited data, leaving room for uncertainty. This is where cost modeling software makes a difference, helping organizations generate consistent, reliable, and data-driven estimates, even in…

Making confident decisions early on can determine whether a project stays within budget and schedule or risks overruns.…

Read blog article