Cost engineering has always been about balancing precision with practicality. Traditionally, it meant managing budgets, monitoring costs, and ensuring that projects delivered value within financial constraints. But today, cost engineering is evolving faster than ever before. The rise of automation, data-driven practices, and artificial intelligence (AI) is transforming how cost engineers approach their work.

This shift isn’t just about technology, but about redefining the role of the cost engineer in a world where decision-making needs to be both faster and smarter. As projects become more complex, the discipline of cost engineering is set to move beyond traditional spreadsheets and manual processes into a future shaped by intelligent automation, predictive analytics, and sustainability-driven strategies.

Automation in Cost Engineering

Automation has already reshaped industries such as manufacturing, finance, and logistics. Cost engineering is no exception. In recent years, historic innovations like real-time cost tracking, digital twins, and advanced project controls software (with real-time links to Scheduling and ERP solutions) have reduced manual workloads and improved the accuracy of forecasts.

Looking ahead, the potential for further automation is significant. For example, machine learning models can now detect anomalies in project data before human engineers notice them, helping to prevent cost overruns. Automated workflows can integrate estimation, scheduling, and cost control/reporting seamlessly, freeing cost engineers to focus on strategic insights rather than repetitive tasks.

Automation doesn’t eliminate the role of cost engineers but rather augments it. The challenge lies in harnessing automation responsibly, ensuring that human expertise still guides decision-making while machines handle the heavy lifting.

AI in Cost Estimation

AI is increasingly being applied in cost estimation, and the results are promising. As explored in our article on AI in Cost Estimation, these technologies analyze historical project data to predict costs with greater accuracy than traditional methods, especially in large-scale and data-heavy industries like construction, oil & gas, and manufacturing. AI also enables probabilistic forecasting, offering not just a single estimate but a range of outcomes based on varying scenarios.

This level of precision reduces uncertainty and allows project stakeholders to make more informed decisions. Beyond estimation, AI can continuously learn from new data, meaning estimates become more accurate over time. For organizations, this represents a shift from reactive cost management to proactive, data-driven planning.

However, it doesn’t stop there. For example, think about an AI agent that will create your estimate completely by just receiving the engineering drawings or equipment lists.

AI in Cost Control

Beyond estimation, AI is also reshaping cost control. Intelligent algorithms can monitor project expenses in real time, flagging unusual patterns or potential overruns before they escalate. Tasks that were once handled through Robotic Process Automation (RPA), such as processing invoices, generating reports, and validating data, are now being absorbed into AI-driven systems.

The result is a smarter, more adaptive approach to cost control, where AI doesn’t just automate tasks but actively improves them. Instead of simply following rules, AI systems can identify trends, recommend corrective actions, and even simulate the financial impacts of different project scenarios. This reduces errors, shortens reporting cycles, and helps organizations manage costs more effectively.

Fully Automated AI vs Cost Engineers?

With so much automation and AI entering the field, the question inevitably arises: Will cost engineers eventually be replaced? The short answer is no. While AI and automation will take over repetitive and data-heavy tasks, human judgment, creativity, and strategic thinking remain irreplaceable.

Cost engineers bring context, negotiation skills, and ethical considerations that machines cannot replicate. The role is likely to evolve from number-crunching to decision-support, with engineers acting as interpreters of AI outputs and strategists for complex projects.

In other words, the future of cost engineering is not about humans versus machines but about humans working with machines. The most successful professionals will be those who embrace technology as an ally, not a competitor.

Sustainability in Cost Engineering

Another emerging trend is the integration of sustainability into cost engineering. As industries face increasing pressure to adopt greener practices, cost engineers are playing a vital role in evaluating the financial implications of sustainable choices.

Here, data availability becomes crucial. The more accurate and transparent the data, the more effectively AI systems can model sustainable cost scenarios, whether it’s the lifecycle costs of renewable materials or the long-term benefits of energy-efficient technologies.

This shift highlights that future cost engineering isn’t just about financial efficiency but also environmental responsibility. Engineers will need to factor in carbon footprints, regulatory requirements, and corporate sustainability goals alongside traditional cost considerations.

5D BIM in Cost Engineering

One last major development in the profession of cost engineering is the increased use of Building Information Modeling (BIM) integrated with cost data (often called 5D BIM).

Traditionally, BIM has been used for 3D design visualization and 4D scheduling (time). Now, with 5D BIM, cost engineers can link cost data directly to project models. This allows for:

- Real-time cost estimation: As designs change, cost impacts are updated instantly, reducing errors from outdated data.

- Improved collaboration: Designers, project managers, and cost engineers work from the same live model, aligning budgets with design intent.

- Scenario planning: Engineers can quickly model multiple design or material choices to see their cost consequences before decisions are made.

- Risk reduction: By connecting schedule and cost data, engineers can better forecast cash flow and resource allocation.

This development is shifting cost engineering toward a more integrated and collaborative discipline, in which engineers are not only financial controllers but also key contributors to design and planning decisions from the very start of a project.

The future of cost engineering will be defined by synergy between humans and machines, efficiency and sustainability, data and design. As automation and AI continue to evolve, the profession’s greatest value will lie not in calculation, but in interpretation, strategy, and foresight.

AI is transforming operations across energy and process (E&P) industries, but behind this evolution lies a challenge: growing…

Operational efficiency in project management is about achieving more with less: delivering projects on time and within budget…

Related resources

AI-Driven Cost Estimation in the Process Industry

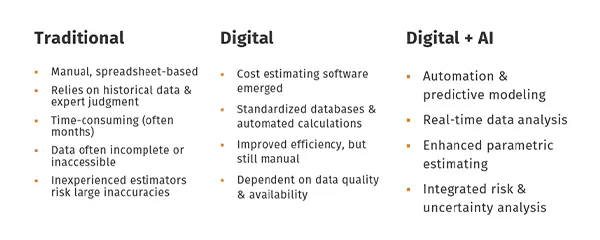

Traditionally, estimators relied on manual calculations, historical data, and expert judgment to forecast costs. However, with advancements in computer technology and artificial intelligence (AI), the cost estimating process is going through a significant transformation.

Read blog article

Common misconceptions about cost engineering

Not everyone is familiar with cost engineering in the field of project controls. Let’s get some common misconceptions out of the way.

Read blog article